Metal theft epidemic copper steel: It sounds like a headline from a dystopian future, but it’s a harsh reality impacting industries worldwide. From construction sites stripped bare to power grids crippled by missing wires, the consequences of this widespread crime are staggering. We’re diving deep into the shadowy world of metal theft, exploring the economic fallout, the ingenious (and sometimes surprisingly clumsy) methods employed by thieves, and the ongoing battle to combat this costly crime wave.

This isn’t just about missing copper wire or stolen steel beams; it’s about the ripple effect – soaring insurance premiums, job losses, and compromised infrastructure. We’ll examine the roles of scrap metal dealers, law enforcement’s challenges, and the innovative prevention strategies being deployed to fight back. Get ready for a gritty look at a problem that’s costing us all – literally and figuratively.

The Economic Impact of Metal Theft

Source: hdnux.com

The metal theft epidemic, targeting copper and steel, is a serious issue, impacting infrastructure and costing billions. Some even connect this to broader societal anxieties, like those fueled by the 15 minute cities conspiracy climate denier narrative, suggesting a breakdown of trust in systems. Ultimately, though, the soaring price of scrap metal remains the primary driver behind this escalating crime wave.

Metal theft, specifically targeting copper and steel, isn’t just a crime; it’s a significant drain on the global economy. The seemingly small act of stealing metal has far-reaching consequences, impacting industries, jobs, and overall economic growth. The financial burden extends beyond the immediate loss of materials; it includes increased security measures, higher insurance premiums, and the disruption of vital services.

Financial Losses Across Industries

The financial losses incurred by industries due to copper and steel theft are staggering. Construction projects face delays and cost overruns when vital materials are stolen from sites. Transportation networks experience disruptions and safety hazards when thieves target railway lines or steal parts from vehicles. Utilities companies face costly repairs and service interruptions due to the theft of copper wiring, impacting electricity and communication services. These losses aren’t merely the cost of the stolen metal itself; they also include labor costs associated with replacing the stolen materials, investigating the theft, and repairing any damage caused. For example, a single theft of copper wiring from a power substation can result in millions of dollars in damages and lost revenue due to power outages affecting homes and businesses.

Ripple Effects on Jobs and Economic Growth

The economic impact of metal theft extends beyond direct financial losses. The theft of essential materials can lead to project delays, causing job losses in construction, manufacturing, and related sectors. Businesses affected by theft may reduce investment, hindering economic growth and potentially leading to further job losses. Increased security costs, necessitated by the rising threat of metal theft, divert resources away from other essential investments, further impacting economic development. The uncertainty created by metal theft also discourages investment in infrastructure projects, slowing down overall economic progress. For instance, repeated thefts from a construction site can lead to project delays, forcing the contractor to lay off workers and potentially leading to the project being abandoned altogether.

Increased Insurance Premiums and Security Costs

Businesses affected by metal theft often face significantly increased insurance premiums. Insurance companies assess the risk associated with metal theft and adjust premiums accordingly. This increase in insurance costs adds to the overall financial burden for businesses, reducing their profitability and competitiveness. Furthermore, the need to implement enhanced security measures, such as improved fencing, surveillance systems, and security personnel, adds substantial costs. These costs, while necessary to deter theft, represent a significant financial investment that could otherwise be allocated to other aspects of the business. A small business owner, for instance, might find their insurance premiums double after experiencing a significant metal theft, severely impacting their financial stability.

Estimated Annual Losses by Sector

| Sector | Estimated Annual Loss (USD) | Example of Impact | Source (Illustrative – Replace with actual data sources) |

|---|---|---|---|

| Construction | $500,000,000 | Project delays, increased costs, job losses | National Association of Builders (Illustrative) |

| Transportation | $200,000,000 | Service disruptions, safety hazards, increased maintenance | Department of Transportation (Illustrative) |

| Utilities | $300,000,000 | Power outages, communication disruptions, costly repairs | National Grid (Illustrative) |

| Manufacturing | $150,000,000 | Production delays, material shortages, increased security costs | Manufacturers Association (Illustrative) |

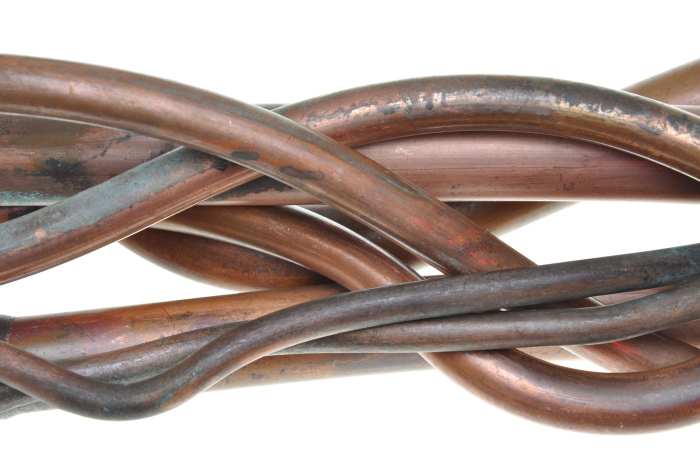

Methods and Techniques Used in Metal Theft

Source: metabolichealing.com

Metal theft, particularly of copper and steel, is a sophisticated operation often involving organized criminal networks. The methods employed range from simple opportunistic grabs to highly organized, planned heists utilizing specialized equipment and inside knowledge. Understanding these techniques is crucial for implementing effective preventative measures.

Copper Wire Theft Methods

The methods used to steal copper wire vary in complexity depending on the target and the thieves’ resources. Simple thefts often involve cutting wires from easily accessible locations, while more sophisticated operations might involve disabling security systems or employing specialized tools to extract large quantities of wire from underground conduits.

- Opportunistic Theft: This involves quickly snipping exposed wires from less secure locations, often using bolt cutters or wire strippers. These thefts are typically small-scale and often target low-hanging fruit like residential wiring or exposed utility lines in less populated areas.

- Targeted Theft from Infrastructure: This involves more planning and often includes disabling alarms, cutting through fences, and utilizing specialized tools to access underground cabling or high-voltage lines. These thefts often involve larger gangs and result in significant losses for utility companies and infrastructure providers. Imagine a crew using a powerful hydraulic cutter to sever a thick bundle of telecom cables under the cover of darkness.

- Sophisticated Operations: These operations involve detailed planning, reconnaissance, and specialized equipment. They might involve disabling security cameras, employing insider knowledge, and utilizing specialized tools for efficient wire extraction. For example, a crew might use a ground-penetrating radar to locate underground cables before excavating them.

Steel Pipe and Beam Theft Methods

Steel theft differs from copper wire theft due to the sheer weight and size of the materials involved. This necessitates different tools and approaches, often involving heavy machinery and transportation.

- Small-Scale Theft: This usually involves cutting smaller sections of steel piping or rebar from construction sites or less secure storage areas. Simple tools like angle grinders and bolt cutters are often used. Think of someone quickly slicing off a piece of rebar from a construction site during the night.

- Large-Scale Theft: This involves stealing larger quantities of steel, often requiring heavy machinery like cutting torches, excavators, and trucks for transportation. Targets often include construction sites, scrap yards, or even railway lines. Picture a team using a cutting torch to sever a large section of steel beam from a partially constructed building, loading it onto a waiting truck, and driving away.

- Organized Crime Involvement: Large-scale steel theft frequently involves organized crime syndicates with access to heavy equipment and transportation networks. They often target larger infrastructure projects or storage facilities, resulting in substantial financial losses and potential safety hazards.

Comparison of Copper and Steel Theft Methods, Metal theft epidemic copper steel

While both copper and steel theft involve the removal of valuable materials, the methods differ significantly due to the properties of the metals. Copper wire is relatively easy to cut and transport in large quantities, making it a popular target for both opportunistic and organized thieves. Steel, on the other hand, requires more specialized tools and equipment for extraction and transportation, making large-scale theft often the domain of organized crime groups. The accessibility of the target also plays a crucial role; exposed copper wire is easier to steal than a securely fastened steel beam.

The Role of Scrap Metal Dealers and Recycling

The scrap metal industry, while vital for resource recovery and economic activity, unfortunately plays a significant, albeit often unwitting, role in the metal theft epidemic. The ease with which stolen metal can be quickly and anonymously converted into cash creates a lucrative, albeit illegal, market that fuels the cycle of theft. Understanding the complexities of this relationship is crucial to tackling the problem effectively.

The ease of selling stolen metal at scrap yards makes them a key facilitator in the metal theft chain. While many scrap yards operate legitimately, the potential for profit from stolen goods makes them attractive targets for thieves. The lack of stringent identification and verification procedures in some yards, coupled with the high value of certain metals, creates an environment ripe for exploitation. This is further complicated by the fact that some scrap dealers may knowingly or unknowingly purchase stolen goods, driven by the desire for higher profits or a lack of robust anti-theft measures.

Measures Taken by Legitimate Scrap Yards to Prevent the Purchase of Stolen Metal

Legitimate scrap yards are increasingly implementing measures to combat the purchase of stolen metal. These measures aim to deter thieves and ensure compliance with legal regulations. Many yards now utilize sophisticated tracking systems, including detailed record-keeping of transactions, photographic identification of sellers, and even the use of metal analysis tools to verify the source and composition of materials. Some yards also actively cooperate with law enforcement agencies, sharing information about suspicious transactions and providing assistance in investigations. These measures, while not foolproof, significantly reduce the likelihood of stolen metal being successfully sold. For example, a scrap yard in Birmingham, UK, implemented a system requiring sellers to provide photographic ID and proof of ownership of the metal, significantly reducing their involvement in stolen metal transactions.

Legal Requirements and Regulations Surrounding Scrap Metal Transactions

Governments worldwide are implementing stricter regulations to curb metal theft. These regulations often mandate scrap yards to maintain detailed records of all transactions, including the seller’s identification, the type and quantity of metal sold, and the price paid. Some jurisdictions also require scrap yards to report suspicious transactions to the authorities. Penalties for non-compliance can be severe, including hefty fines and even closure of the business. For instance, the US has various state and federal laws regulating scrap metal transactions, including mandatory record-keeping, and the UK’s Scrap Metal Dealers Act 2013 introduced stricter regulations, requiring licensing and detailed record-keeping. These laws aim to increase transparency and accountability within the industry.

A Flow Chart Illustrating the Process of Selling Scrap Metal

The process of selling scrap metal, from the initial acquisition of the material to the final payment, contains several vulnerabilities that can be exploited by thieves.

[Imagine a flowchart here. The flowchart would begin with “Acquisition of Scrap Metal” branching into two paths: “Legitimate Source” (e.g., demolition, construction) leading to “Transportation to Scrap Yard” then “Verification and Payment”, and “Illegitimate Source” (theft) leading to “Transportation to Scrap Yard” then “Potential for Detection/Non-Detection” branching into “Successful Sale/Payment” and “Apprehension”]. The flowchart visually highlights the points where stolen material might enter the system and the potential points of interception for law enforcement or scrap yard procedures. The key vulnerabilities lie in the lack of verification at the scrap yard and the anonymity afforded to the seller. The absence of robust identification checks and the ease of cash transactions create opportunities for thieves to dispose of stolen goods with minimal risk.

Law Enforcement and Legal Responses

Combating metal theft presents a unique set of challenges for law enforcement agencies worldwide. The often-unassuming nature of the crimes, coupled with the ease of transporting and reselling stolen materials, makes detection and prosecution difficult. Furthermore, the sheer volume of scrap metal transactions, combined with the lack of robust tracking systems in some areas, creates a fertile ground for illicit activity to flourish.

The challenges faced by law enforcement in combating metal theft are multifaceted. Identifying the perpetrators is often difficult, as metal theft is frequently opportunistic and committed by individuals who may not have a history of similar crimes. The decentralized nature of the scrap metal industry also hampers investigations, as stolen metal can quickly change hands, making tracing its origins a complex task. Additionally, securing sufficient evidence to build a strong case for prosecution can be time-consuming and resource-intensive, requiring close collaboration between law enforcement agencies and scrap metal recyclers. Limited resources and competing priorities within law enforcement agencies often mean that metal theft is not always given the attention it deserves.

Penalties and Punishments for Metal Theft

Penalties for metal theft vary significantly depending on the jurisdiction, the value of the stolen metal, and the offender’s prior criminal record. In many jurisdictions, metal theft is considered a felony offense, particularly if the theft involves significant quantities of material or causes substantial economic damage. Common penalties include fines, imprisonment, and restitution to the victims. For repeat offenders or cases involving organized crime, sentences can be significantly harsher. For instance, a first-time offender caught stealing a small amount of copper might receive a fine and probation, while someone involved in a large-scale operation targeting critical infrastructure could face lengthy prison sentences and substantial financial penalties. The severity of the punishment aims to deter future offenses and compensate victims for their losses.

Successful Strategies to Reduce Metal Theft

Several strategies have proven effective in reducing metal theft. Improved tracking and registration systems for scrap metal, requiring dealers to meticulously document the source of all materials received, have been shown to significantly curb illicit activity. Enhanced collaboration between law enforcement agencies, scrap metal dealers, and infrastructure owners allows for the rapid sharing of information and coordinated enforcement efforts. Targeted patrols in areas known for high metal theft rates, coupled with the use of technology such as GPS tracking and surveillance cameras, can also deter potential thieves and assist in apprehending offenders. Public awareness campaigns educating the public about the risks of metal theft and the importance of reporting suspicious activity can also contribute to a reduction in crime. For example, a successful campaign in the UK involved working with local communities to identify theft hotspots and implement preventative measures.

Effectiveness of Different Legal Approaches

The effectiveness of different legal approaches to metal theft varies across jurisdictions. Some jurisdictions have implemented stricter regulations on scrap metal dealers, requiring them to obtain licenses and maintain detailed records of their transactions. Other jurisdictions have focused on increasing penalties for metal theft, while others have prioritized community-based approaches, such as educational programs and public awareness campaigns. A comparative analysis of these different approaches reveals that a multi-pronged strategy, combining stricter regulations, increased penalties, and community engagement, is often the most effective in reducing metal theft. Jurisdictions with strong partnerships between law enforcement and scrap metal dealers tend to see greater success in reducing crime, demonstrating the importance of collaboration in combating this type of theft.

Prevention and Mitigation Strategies

The escalating costs and disruptions caused by metal theft demand proactive and comprehensive prevention strategies. Combating this crime requires a multi-pronged approach encompassing robust security measures, technological advancements, employee awareness, and strong community partnerships. Ignoring these preventative measures only invites further losses and societal disruption.

Effective prevention hinges on making metal theft a difficult, risky, and ultimately unprofitable endeavor. This involves a combination of physical security enhancements, technological deterrents, and a well-informed workforce. The ultimate goal is to significantly raise the barrier to entry for thieves, making other targets more appealing.

Physical Security Measures

Implementing robust physical security is the cornerstone of any effective metal theft prevention plan. This includes measures such as installing high fences topped with barbed wire or razor wire to deter unauthorized access. Strong, well-lit perimeters significantly reduce the opportunity for covert operations. Regular patrols, either by security personnel or via CCTV monitoring, serve as a powerful deterrent. Secure storage facilities for materials, equipped with locks and alarms, are crucial. Consider using heavy-duty chains and locks for securing valuable metal items. For example, a construction site could employ reinforced cages around stored copper piping, making removal incredibly difficult and time-consuming. The added cost of enhanced security is far outweighed by the potential losses from theft.

Technological Solutions

Technology offers powerful tools to combat metal theft. GPS tracking devices embedded in or attached to valuable metal items allow for real-time monitoring and rapid recovery in case of theft. Smart sensors, triggered by vibrations or unauthorized movement, can instantly alert authorities or security personnel to suspicious activity. These sensors can be strategically placed on valuable equipment or storage containers. For instance, a scrap yard could use weight sensors on incoming loads to detect discrepancies between declared and actual weight, potentially indicating the presence of stolen metal. Furthermore, video surveillance systems with advanced analytics can detect unusual activity and automatically alert relevant personnel.

Employee Training and Awareness Programs

A well-trained and vigilant workforce is a critical element in preventing metal theft. Regular training programs should educate employees about the risks of metal theft, the common methods used by thieves, and the importance of reporting suspicious activity. Employees should be made aware of the company’s security protocols and their role in maintaining a secure environment. This includes understanding proper procedures for securing materials, reporting missing items, and identifying potential security vulnerabilities. Role-playing scenarios and regular security audits can reinforce these lessons and identify weaknesses in existing procedures. A culture of security awareness, where employees are empowered to report suspicious behavior, is invaluable.

Community Involvement and Partnerships

Effective metal theft prevention requires a collaborative effort between businesses, law enforcement, and the community. Partnerships with local law enforcement can facilitate information sharing and coordinated responses to theft incidents. Community watch programs can help identify suspicious activity and report it to authorities promptly. Working with scrap metal dealers to establish robust record-keeping and verification procedures helps prevent the sale of stolen metal. This collaboration ensures that stolen materials cannot be easily fenced and that thieves are less likely to find willing buyers. Open communication channels between businesses and residents in high-risk areas can create a more vigilant and protective environment.

Best Practices for Businesses and Individuals

- Implement robust physical security measures, including fencing, lighting, and secure storage.

- Utilize GPS tracking and smart sensors to monitor valuable metal assets.

- Conduct regular security audits and employee training programs.

- Establish strong relationships with local law enforcement and scrap metal dealers.

- Report any suspicious activity to authorities immediately.

- Mark valuable metal items with unique identifiers to aid in recovery.

- Consider using metal alloys that are less attractive to thieves.

- Insure valuable metal assets against theft.

The Environmental Impact of Metal Theft: Metal Theft Epidemic Copper Steel

Source: themetalmagazine.com

Metal theft, while often perceived as a purely economic crime, carries significant and far-reaching environmental consequences. The illegal extraction and improper disposal of stolen metals contribute to pollution, resource depletion, and damage to critical infrastructure, ultimately impacting the health of our planet and communities. Understanding these environmental ramifications is crucial to effectively combatting this pervasive problem.

Improper Disposal of Stolen Metal and its Environmental Consequences

The haphazard disposal of stolen metals poses a significant threat to the environment. Stolen copper, for example, often ends up in landfills or illegally dumped in waterways, rivers, and even forests. This practice contaminates soil and water sources with heavy metals like copper, lead, and zinc, which are toxic to both wildlife and humans. The leaching of these heavy metals into the ecosystem can cause long-term damage to plant life, disrupt aquatic ecosystems, and even enter the food chain, potentially impacting human health through bioaccumulation. Similarly, the improper disposal of steel can lead to rust and the release of harmful chemicals into the environment. The scale of this problem is often underestimated, as many illegal dumping sites go undetected and unremediated.

Impact on Infrastructure and Public Safety

Metal theft significantly compromises infrastructure and public safety. The theft of copper wire from electrical substations, for instance, can lead to power outages, disrupting essential services and impacting businesses and residential areas. The subsequent repair costs are substantial, and the downtime can cause significant economic losses. Furthermore, the theft of metals from railway tracks, bridges, and other critical infrastructure components creates serious safety hazards, potentially leading to accidents and injuries. The weakening of these structures due to the removal of essential metal components poses a significant risk to public safety, requiring costly repairs and extensive safety assessments.

Energy Consumption in Metal Replacement

Replacing stolen metal requires significant energy consumption. The production of new metals, particularly copper and steel, is an energy-intensive process. Producing a single ton of steel, for example, requires substantial amounts of coal and other fossil fuels, contributing to greenhouse gas emissions and air pollution. Similarly, copper refining is an energy-consuming process that involves complex chemical reactions and high temperatures. The energy expended in replacing stolen materials adds to the overall carbon footprint, exacerbating climate change and contributing to environmental degradation. Consider a scenario where a significant amount of copper wiring is stolen from a large industrial complex; the energy required to produce replacement wiring is considerable, representing a substantial environmental cost.

Visual Representation of Environmental Damage

Imagine a polluted riverbank, littered with discarded copper wire and rusted steel components. The water is murky and discolored, reflecting the leaching of heavy metals from the discarded materials. Nearby vegetation is stunted and withered, a testament to the toxic soil conditions. Further inland, illegally dumped scrap metal is slowly rusting, contaminating the surrounding soil and potentially seeping into groundwater. This visual represents the cumulative environmental damage caused by irresponsible handling of stolen metal, illustrating the interconnectedness of pollution, resource depletion, and public safety risks. The scene is a stark reminder of the long-term environmental consequences of metal theft, extending beyond the immediate economic losses.

Epilogue

The metal theft epidemic, particularly targeting copper and steel, is a complex problem demanding multifaceted solutions. While law enforcement plays a crucial role in apprehending thieves and prosecuting offenders, the fight against this crime hinges on a collaborative effort. Increased security measures, stricter regulations on scrap metal dealing, public awareness campaigns, and technological advancements are all vital in disrupting the supply chain and deterring future thefts. Ultimately, overcoming this epidemic requires a collective commitment to protecting our infrastructure and our economy from the devastating impact of metal theft.